Jewelry making is a timeless craft that combines artistry, precision, and intricate techniques. Among the various professionals involved in this field, the laser operator plays a crucial role in modern jewelry manufacturing. This blog explores the responsibilities, skills, and significance of a laser operator in the jewelry industry.

Introduction to Laser Technology in Jewelry Making

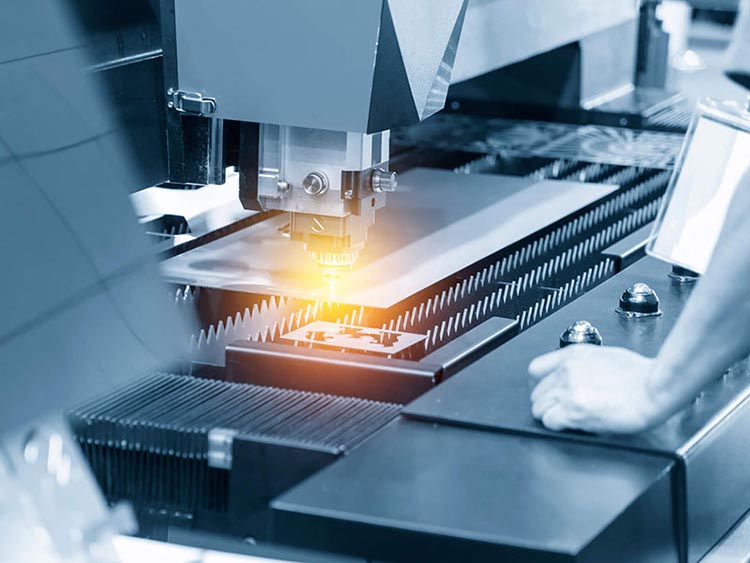

Laser technology has significantly transformed jewelry making by offering precision, efficiency, and new design possibilities. Introduced in the late 20th century, lasers have become an indispensable tool for jewelers. They are used in various applications such as cutting, engraving, welding, and marking.

One of the primary advantages of laser technology is its precision. Lasers can cut intricate patterns and shapes with remarkable accuracy, which is difficult to achieve with traditional tools. This allows jewelers to create complex designs that were previously impossible or too time-consuming.

Engraving with lasers also offers unparalleled detail. Whether it’s adding personalized messages, intricate patterns, or even images, the fine control of laser beams ensures high-quality results. Additionally, laser engraving is a non-contact process, meaning it doesn’t exert force on the jewelry piece, reducing the risk of damage.

Laser welding is another significant advancement. Traditional soldering methods can be imprecise and risk damaging delicate pieces. Laser welding, however, allows for pinpoint accuracy, making it ideal for jewellery repairing or resizing jewelry without compromising its integrity.

Furthermore, lasers facilitate the marking of metals with serial numbers, trademarks, or other identifiers, ensuring authenticity and traceability. This is especially important in high-value items where provenance is crucial.

Responsibilities of a Laser Operator

1. Operating Laser Machinery

Operating laser machinery as a laser operator involves precision and attention to detail. Laser machines are used in various industries, including manufacturing, medical, and research. The operator’s role is crucial for ensuring that the laser cuts, welds, or engraves materials accurately.

Before starting, the operator sets up the machine according to specific instructions, which include adjusting settings like power, speed, and focus. Safety is paramount, so wearing protective gear such as goggles and gloves is mandatory. Operators must be familiar with the machine’s safety protocols to prevent accidents.

Once the machine is set up, the operator loads the material and initiates the process. Monitoring the operation is essential to ensure that the laser performs as expected. Adjustments might be needed if the cut or engraving isn’t precise. After the job is completed, the operator inspects the finished product for quality control.

Maintenance of the laser machine is another key responsibility. Regular cleaning and calibrating keep the equipment in optimal condition. Troubleshooting minor issues and performing routine checks prevent downtime and extend the machine’s lifespan.

Being a laser operator requires technical skills, a keen eye for detail, and strict adherence to safety standards.

2. Precision Cutting

One of the primary functions of a laser operator is precision cutting. Lasers can cut through metals and gemstones with remarkable accuracy, allowing for intricate designs that would be challenging to achieve using traditional methods. The operator must carefully plan and execute cuts to ensure that each piece meets the designer’s specifications.

3. Engraving and Marking

Laser engraving and marking are essential for adding intricate details and personalization to jewelry pieces. Whether it’s adding a monogram, intricate patterns, or hallmarking, the laser operator must have a keen eye for detail and steady hands to ensure perfect execution. Engraving requires an understanding of different materials and how they react to laser exposure.

4. Welding and Soldering

Laser welding and soldering are used to join pieces of metal with precision and minimal heat distortion. This technique is particularly useful for delicate jewelry pieces where traditional soldering methods might damage the item. The laser operator must be skilled in controlling the laser’s intensity and focus to create strong, clean joints without compromising the integrity of the piece.

5. Quality Control

Quality control is a critical aspect of a laser operator’s job. They must inspect each piece of jewelry after processing to ensure it meets the required standards. This involves checking for accuracy, consistency, and any potential defects that could affect the final product’s appearance or durability.

Essential Skills for a Laser Operator

1. Technical Proficiency

Operating laser machinery requires a high level of technical proficiency. The operator must understand how to set up, calibrate, and troubleshoot complex equipment. Knowledge of various software programs used to design and control laser operations is also essential.

2. Attention to Detail

Jewelry making demands precision, and even the smallest error can ruin a piece. A laser operator must have exceptional attention to detail to ensure that every cut, engraving, or weld is executed flawlessly.

3. Artistic Sensibility

While technical skills are crucial, an artistic sensibility is equally important. The operator must understand design principles and aesthetics to translate a designer’s vision into reality. This involves making creative decisions about how to best use laser technology to enhance the beauty of each piece.

4. Problem-Solving Skills

Jewelry making can present unexpected challenges, such as dealing with materials that react unpredictably to laser exposure. A skilled laser operator must be able to think on their feet and find solutions to any issues that arise during the production process.

5. Communication Skills

Effective communication is vital in a collaborative environment like a jewelry workshop. The laser operator must work closely with designers, jewelers, and other team members to ensure that everyone is on the same page and that the final product meets all expectations.

The Impact of Laser Operators on Jewellery Design

1. Innovation in Design

The precision and versatility of laser technology have opened up new possibilities for jewelry design. Laser operators can create intricate patterns, detailed engravings, and complex shapes that were previously impossible or extremely difficult to achieve. This has led to a surge in innovation within the industry, with designers pushing the boundaries of what can be created.

2. Customization and Personalization

Lasers allow for a high degree of customization and personalization in jewelry making. From custom engravings to bespoke designs tailored to individual preferences, laser operators play a key role in creating unique pieces that resonate with customers on a personal level.

3. Efficiency and Consistency

Laser technology streamlines many aspects of the jewelry-making process, making it more efficient and consistent. Laser operators can produce multiple identical pieces with precision, ensuring that each item meets the same high standards. This is particularly valuable for mass production or creating matching sets of jewelry.

4. Preservation of Traditional Craftsmanship

While lasers bring modern technology into jewelry making, they also help preserve traditional craftsmanship by enabling finer details and more precise work than what might be possible by hand alone. Laser operators bridge the gap between old and new techniques, enhancing traditional methods with contemporary precision.

Training and Education for Laser Operators

Becoming a skilled laser operator in the jewelry industry requires specialized training and education. Many operators start with a background in jewelry making or a related field before specializing in laser technology. Training programs may include:

1. Technical Courses

Technical courses cover the fundamentals of laser technology, including how lasers work, safety protocols, and basic operation techniques. These courses provide a solid foundation for understanding the machinery.

2. Hands-On Training

Hands-on training is essential for gaining practical experience with laser equipment. This often involves working under the guidance of experienced operators or technicians to learn advanced techniques and troubleshooting skills.

3. Design Software

Familiarity with design software is crucial for creating precise patterns and engravings. Training programs often include instruction on using computer-aided design (CAD) software and other tools used to control laser operations.

4. Material Science

Understanding how different materials react to laser exposure is vital for achieving optimal results. Courses in material science teach operators about the properties of various metals and gemstones, as well as how to work with them effectively.

Conclusion

The role of the laser operator in jewelry making is both challenging and rewarding. These skilled technicians bring together technical expertise, artistic sensibility, and meticulous attention to detail to create stunning pieces of jewelry that push the boundaries of design and craftsmanship. As laser technology continues to evolve, the contributions of laser operators will remain essential to the innovation and growth of the jewelry industry.

In summary, a career as a laser operator offers an exciting blend of modern technology and traditional artistry. It requires dedication, continuous learning, and a passion for creating beautiful, enduring works of art that capture the imagination and delight customers around the world.